The Foundation of Manufacturing Quality

At XSF, our commitment to quality starts with a strong foundation. From maintaining safe and efficient equipment to inspecting raw materials with precision, every step we take ensures that our trusses meet the highest standards.

In Part 2 of this series, we’ll explore the first crucial stages of our 9-step quality control process and how they set the tone for XSF excellence.

How XSF Combines Safety and Strength for Superior Truss

Safety and Equipment: A Foundation for Precisions

Safety is at the heart of everything we do. While it may not directly affect the quality of the truss itself, maintaining safe, well-functioning equipment is critical to efficient and reliable production.

The XSF team takes equipment maintenance seriously, ensuring that all tools and machinery are clean, inspected, and repaired when needed. By prioritizing safety, we create an environment where craftsmanship thrives.

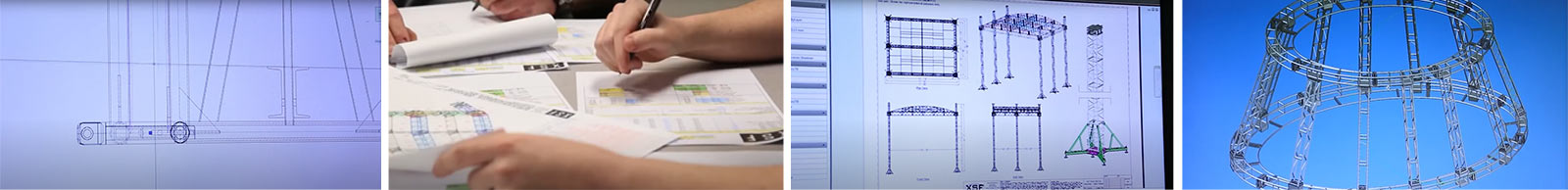

Fabrication Drawings and Engineering: From Vision to Reality

The journey from concept to creation starts with fabrication drawings and engineering. This stage is where creative ideas take shape, transforming into detailed plans that are ready for production.

• Every project is carefully reviewed with customer input to ensure alignment with their vision.

• 3D fabrication drawings, including any necessary engineering requirements, are shared with customers for approval before moving to the XSF shop floor.

This attention to detail guarantees that every truss that leaves XSF meets customer expectations and delivers on the precision and reliability they have come to depend on.

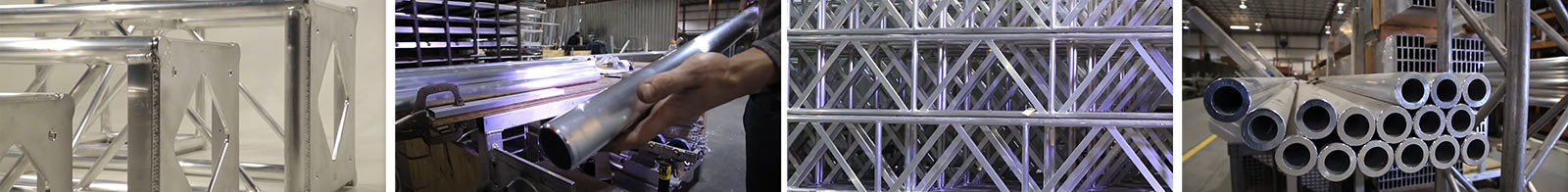

Raw Materials: Receiving and Inspection

Not all aluminum is created equal, and at XSF, we only work with the best.

- Our team performs rigorous inspections of all raw aluminum materials upon delivery to ensure it meets the highest industry standards.

- Materials that fail to meet these standards are immediately rejected.

Every truss starts with 6005A or 6061 aluminum alloy, known for its strength and versatility. We also provide material certifications upon request, offering transparency and peace of mind to our customers.

What’s Next in PART 3?

In the next post, we’ll delve deeper into the cutting, welding, and assembly processes—key stages where precision and craftsmanship meet. Stay tuned as we continue this journey through XSF’s 9-step quality control process.

Ready to Learn More?

We invite you to watch the XSF Quality Control Video on YouTube to see these processes in action.

From maintaining safe equipment to turning engineering designs into reality, the video provides an even closer look at what makes XSF trusses exceptional.

For More Information on XSF Quality Control Visit our Quality Control Page

Visit the XSF TRUSS DRAWINGS LIBRARY

Solidworks | Vectorworks | AutoCad | DAE | Sketch up | Blender | STL

XSF Quality Control Video at YouTube

A behind-the-scenes look at our facility and offers even more insights into how XSF maintains the highest standards for its customers.