Cutting, Welding, and Assembling with Precision

At XSF, the heart of our manufacturing facility and manufacturing process lies cutting, welding, and assembly. These steps are where raw materials are transformed into precision-engineered trusses or fabricated pieces that meet the most demanding performance standards.

In Part 3 of this series, we’ll explore how craftsmanship, expertise, and attention to detail come together to deliver superior results.

Crafting Excellence: The Cutting, Welding, and Assembly Process

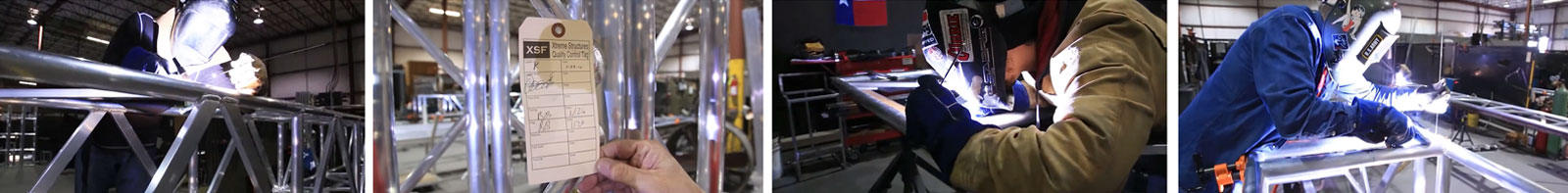

Truss Welding: Strength and Reliability

Every XSF Truss starts with certified welding.

- Our welders are certified by the American Welding Society (AWS), ensuring they meet the highest industry standards.

- Each Aluminum part is inspected against the fabrication drawings before being placed in jigs for welding.

- Welds are completed using the strongest aluminum filler wire available and are visually inspected to confirm quality before moving to the next step.

This meticulous process ensures that every weld contributes to the structural integrity and safety of the final product.

Precision Cutting and Machining

Accuracy is critical in truss manufacturing, and that begins with precision cutting and machining.

- Raw materials are carefully cut and machined to exact specifications outlined in the fabrication drawings.

- Our cutting specialists inspect each piece for defects, rejecting anything that doesn’t meet the XSF standard.

Every Truss piece is then tagged, signed, and dated as part of our quality control process, ensuring accountability at every stage.

Final Assembly and Test Fit

Before any truss moves on to the finishing stage, it undergoes final assembly and test fitting.

- Components are inspected and fitted together to confirm they align perfectly with the fabrication drawings.

- For custom projects, this step is essential to ensure the truss system performs as intended. This step guarantees that when your project arrives everything fits exactly as specified.

Every truss that leaves our facility is tested to ensure it meets the highest standards of reliability and precision.

What’s Next in PART 4?

Stay tuned for Part 4, where we’ll dive into the finishing touches that give XSF trusses their polished, professional or powder coated color look. From cleaning and inspection to surface finishes, you’ll see how we bring the process to a flawless conclusion.

Ready to Learn More?

We invite you to watch the XSF Quality Control Video on YouTube to see these processes in action.

From maintaining safe equipment to turning engineering designs into reality, the video provides an even closer look at what makes XSF trusses exceptional.

For More Information on XSF Quality Control Visit our Quality Control Page

Visit the XSF TRUSS DRAWINGS LIBRARY

Solidworks | Vectorworks | AutoCad | DAE | Sketch up | Blender | STL

XSF Quality Control Video at YouTube

A behind-the-scenes look at our facility and offers even more insights into how XSF maintains the highest standards for its customers.